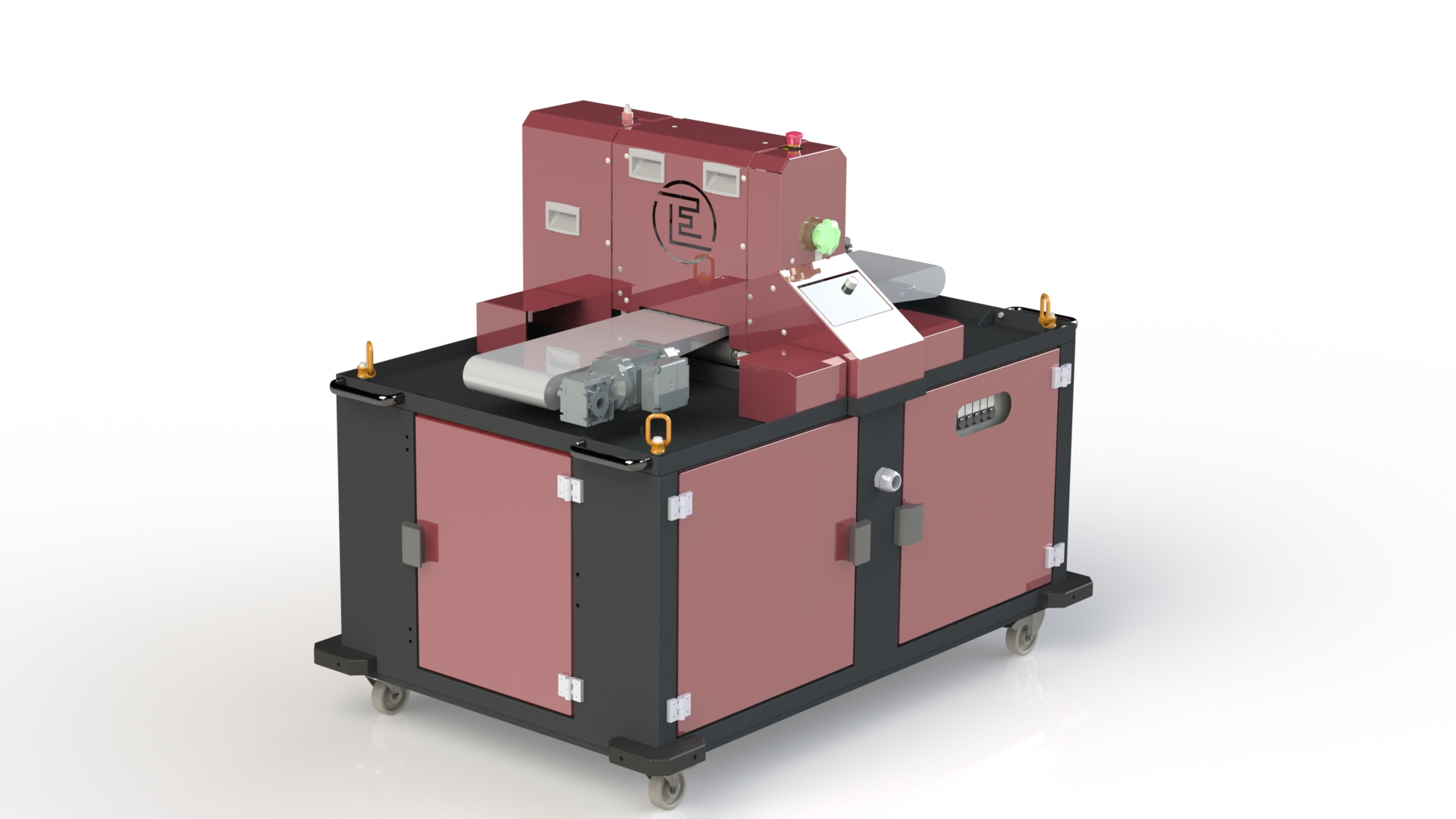

Compact and utilizable in literally all directions: The all-in lubrication carts by Eckardt carry a busload of benefits, especially if there is little room for maneuver or different work areas have to be served without having much time for extensive retooling. All of these amenities struck a chord with a leading automotive supplier from Upper Franconia (State of Bavaria) who ordered an Eckardt lubrication cart for its Hungarian production site.

The customized cart measures ca. 1.60 m in length, 1.10 m in width and 1.40 m in height and is suitable for material widths of up to 250 mm.

Exclusive lubrication technology

At the heart of the construction is a ROTOL squeeze-on lubricator, an exclusive in-house development by Eckardt. The interplay of a stationary squeeze-roller and a movable distributor roller generates high pressure, enabling the lubricant to be squeezed onto the material absolutely homogeneously in very thin layers. A powered conveyor belt on the infeed and outfeed side of the machine transport the blanks through the lubrication unit.

Easily accesible

A specially designed Eckardt dosing system is responsible for the supply of lubricants from the interior of the cart. It is mounted on a telescopic arm which can be easily pulled out for refilling even if there is little room available. Equally accessible, the dosing control unit is integrated into the small side of the lubricator.

All-around, robust doors protect the interior and make the cart visually appealing as well.