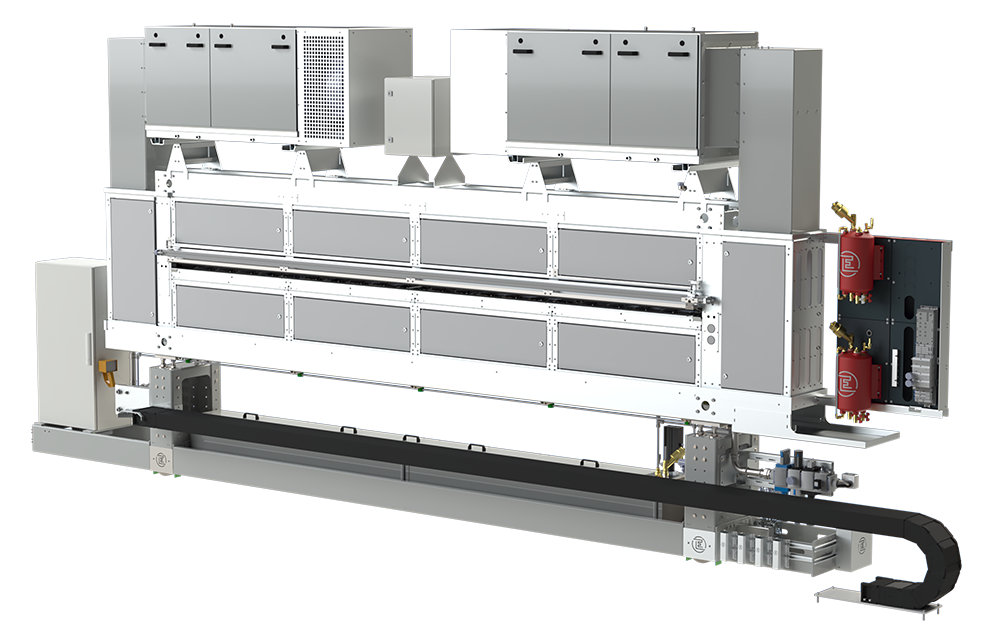

Compact, slim, powerful. Compared to the tried and tested EOS systems the new EQS (“Eckardt Quality Spaying”) machines are significantly slimmer and therefore perfectly suited for the actual space conditions in many press shops. The modular construction concept for components such as basic frame, spray chamber and oil supply requires shorter production and delivery times and offers greater flexibility in adjusting to individual customer requirements for the forming process.

Spray chamber

The spray chamber of the EQS systems hosts two spray bars (top/bottom), which are made of an Eckardt aluminum profile and are equipped with individually adjustable spray nozzles. The back side of the spray bars is heated; the temperature of the lubricant before production can be set using the control unit.

An all-round closed cabinet made of zinc-coated sheet steel encloses the spray chamber, sparing only the guide trenches for the blanks and the fittings for the oil mist separators. Via removable sheet metal coverings and swing doors the chamber provides easy access for repair and maintenance work. The lower part also serves as a drain tray for surplus oil, which flows back into the holding tank and does not leave the closed oil circuit.

Oil mist extraction

The integrated EONA 3000 filter system is composed of two multi-stage filter units, the last one of which is equipped with F9 filter grade efficiency and extracts even the smallest particles. The pressure difference measured right after the filter pass-through gives information about the degree of filter pollution. The control system releases warning messages in due time so that polluted filters can be replaced before they have an impact on process efficiency.

Spray patterns

The control system of the EQS designed by Eckardt allows for easy definition and assignment of spray patterns. They can be generated with the utmost flexibility regarding the particular lubrication requirements of the blanks. Depending on the spray nozzle series used different lubricant quantities may be assigned to each field, either graded in relation to the “whole load” or in pre-defined absolute quantities.

The direct import of CAD data formats such as DXF and DWG into the gird enables you to easily decide where lubrication on either side of the blank is really necessary.

Combination with LBE brush cleaner

The new EQS spray lubricator is particularly well suited for joint operation with the LBE brush cleaning system by Eckardt. The latter ensures best cleaning results throughout by using market-leading brush technology, including cutting-edge features such as a brush correction system which helps the bristles stay in their upright position while processing blanks of varying thickness.

One control station, one control cabinet, one interface: Both Eckardt machines can be adjusted and operated using a single control device. The parameters for material and spraying set in the EQS lubricator are automatically released to the LBE brush cleaner. Moreover, many of the same spare parts are applicable to both systems, e.g. regarding oil mist extraction, pneumatics and under-carriage. In this respect, the combination also has the potential for substantial cost-savings.