The oft-quoted “velvet gloves” are essential for the production of thin, sensitive saw blades. In the case of our customer, we had to find a way for spraying corrosion protection oil on material widths of up to 30 mm and thicknesses of up to 3 mm. Another treat: the saw blades have to be processed in an upright position.

Spraying technology turned 90 degrees

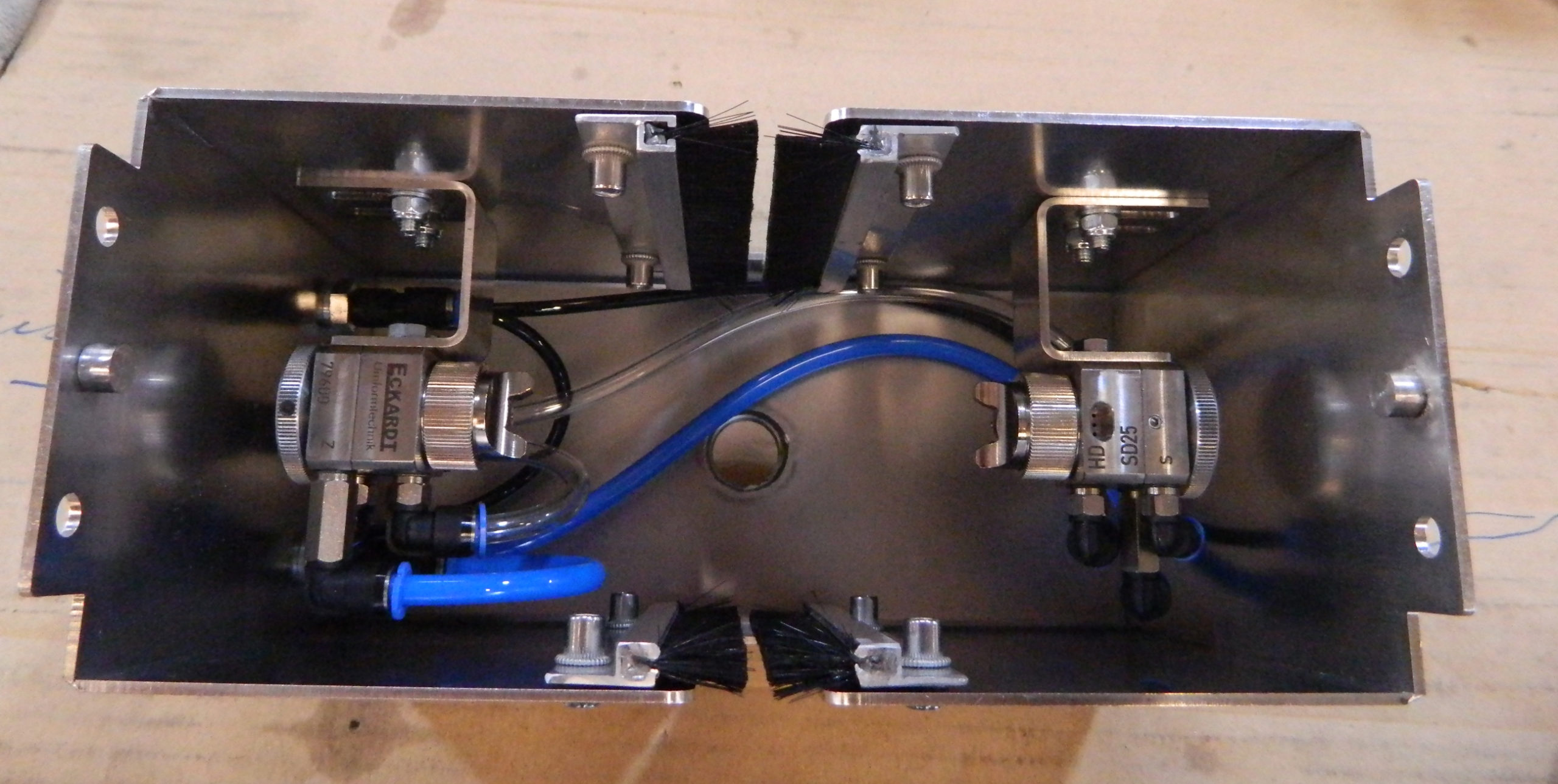

The most obvious strategy was the one we finally pursued – that is, we also turned our spraying technology 90 degrees and dveloped an “upright” version of our spray lubrication unit EOS 1, exactly tailored to the specific customer requirements.

Inside the spray chamber each spray bar on the left and right side features one spray nozzle. The chamber is made of robust stainless steel and closed all around, except for the passage gaps for the material. A pair of brushes is attached to the gaps in order to keep the oil mist from emanating. The bottom the unit also serves a a drop down tray for dripping oil or oil which has been sprayed past the material edges. The retained oil is then forwarded to a container using a tube.

Two-medium nozzle SD 25 HD

The spray job is carried out by the Eckardt nozzle type SD 25 HD. It is a two-medium configuration, meaning that the lubricant is exposed to swirling air and expelled from the nozzle in the form of oil mist. The nozzle includes a needle which changes the profile of the outfeed opening and therefore the flow rate, depending on its position. An increase or decrease in spray air pressure affects the degree of atomization and, as a result, the dispersion of the lubricant on the material surface.

The lubricant is provided from a pressurized container. Changing the air pressure manually increases or decreases the amount of lubricant supplied to the spray unit and eventually the coating thickness on the material.

It goes without saying that the Eckardt spray lubricants do not only cut a fine figure when processing saw blades in a way out of the ordinary. Here you can find additional information on this business segment.