Thin – thinner – Eckardt. If lubricants have to be applied in very fine layers, there’s no way around our squeeze-on lubricators, our exclusive in-house development. This is how a leading steel producer located in Belgium decided to proceed when looking for a lubrication solution for material of up to 1.650 mm in width and 3 mm in thickness.

Pressure and flatten

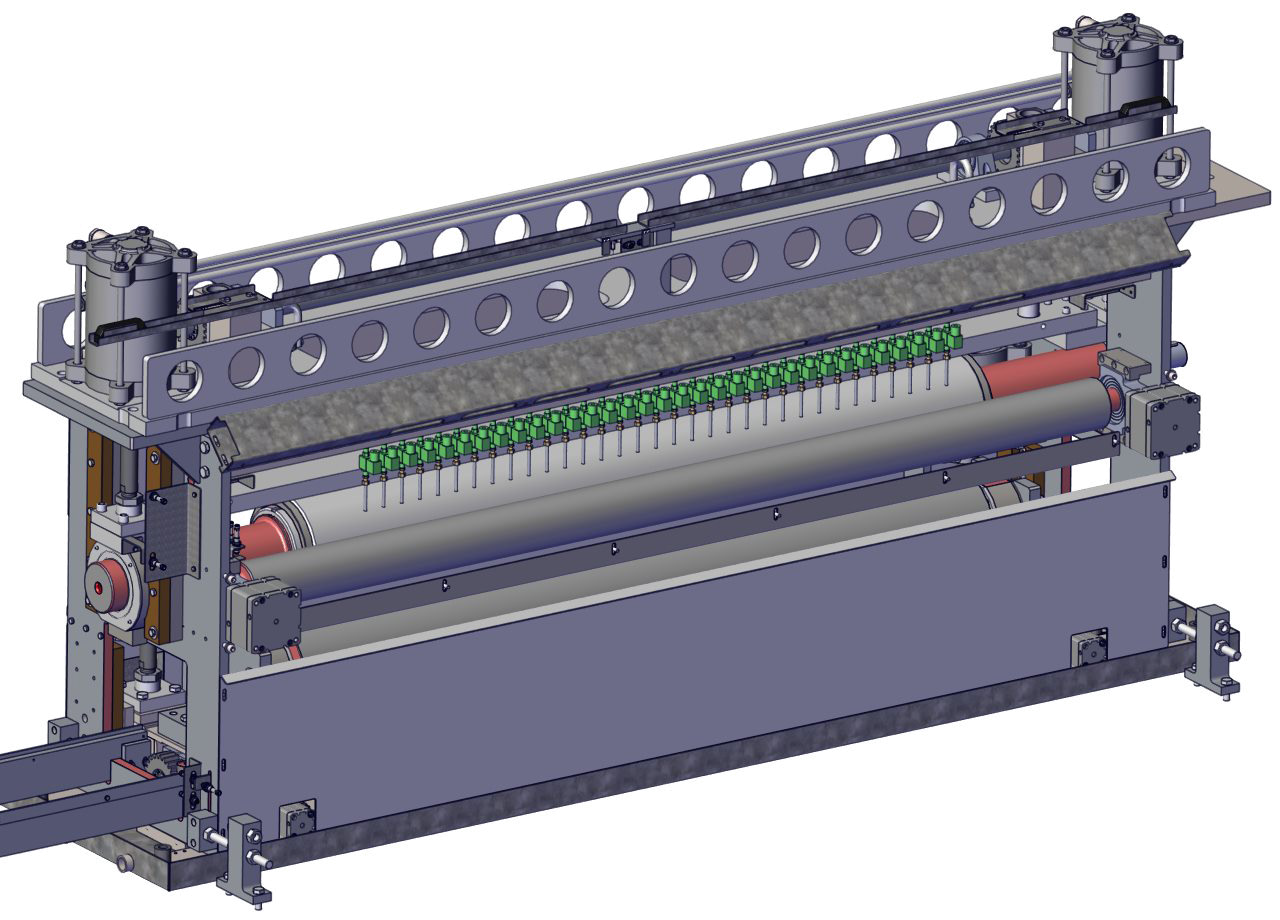

Especially for larger dimensions like these, the Eckardt squeeze-on lubricators have a lot to offer. The application of lubricants is based on the interplay of two roller systems: a squeezer and a distributor roller. Via magnet valves the lubricant is fed between both rollers and absorbed by the open pores of the robust squeezer coating.

Meanwhile the distributor roller applies increasing pressure to its counterpart causing the lubricant to flatten into a thin film, which is then homogeneously squeezed onto the material surface passing through the lubricator. If the pressure acting upon the squeezer roller drops, the pores open up and can absorb another round of lubricant.

This method has several advantages: Film thickness relies on roller pressure and roller gap – two easily reproducible factors, which ensure maximum process reliability. Moreover, the technique is very economical in terms of lubricant consumption and it is perfectly suitable for all types of fluid lubricants and viscosities, even through to grease.

Easy roller access

The lower roller rests upon a crossbar, which can be pulled out, offering very easy and comfortable access to the inner area of the machine for maintenance work and adjustments. This is no small benefit given that the lubricator is about 5 m in total length and weighs in at some 3.5 tons, making it one of the largest squeeze-on systems ever to leave the Eckardt production site!

If you want to learn more about this exclusive lubrication technique, please refer to the product page.